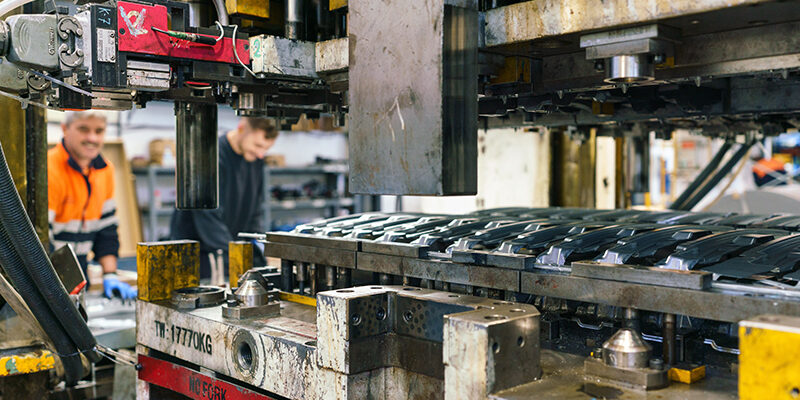

Our team of experts excels in metal stamping, delivering high-quality solutions in metal parts manufacturing. We operate with strip widths of up to 1500mm and thicknesses ranging from 0.5mm to 7mm. With over 50 years of experience, we assure products with superior performance and durability.

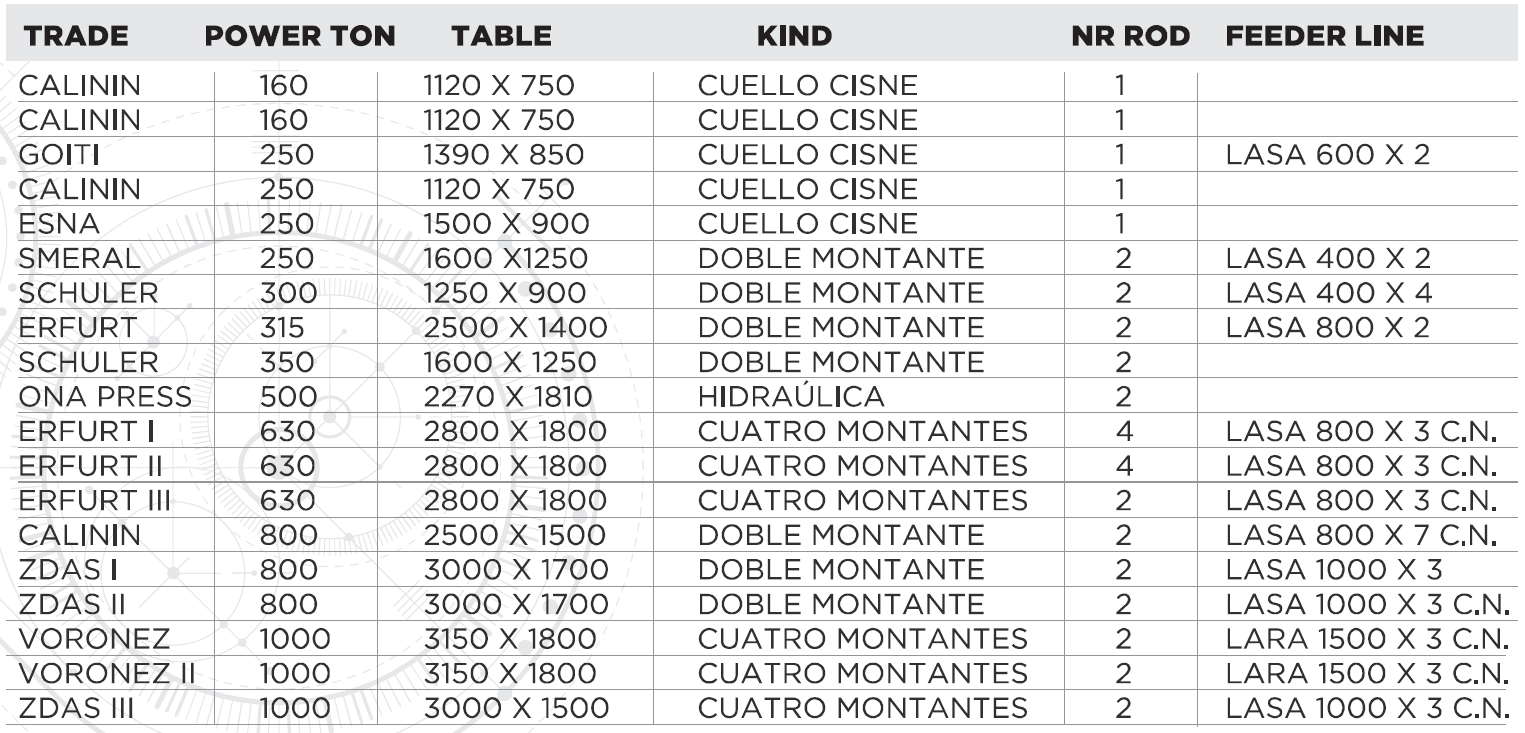

We possess high-tonnage presses, tailoring production to the specific needs of each client, ensuring personalised and efficient outcomes.

Thanks to our extensive machine park, we have backup presses to guarantee continuous production in the event of unforeseen circumstances. This also allows us to perform maintenance on our presses.

Metal stamping is pivotal across sectors such as automotive, aerospace, electronics, and construction. Our expertise enables us to collaborate with clients in these industries, providing tailored solutions for each project.

We invest in research and development, continually enhancing our processes and providing the latest innovations in metal stamping. By choosing Manufacturas Cruce, clients benefit from our expertise and technical knowledge, ensuring top-quality parts perfectly tailored to their needs.